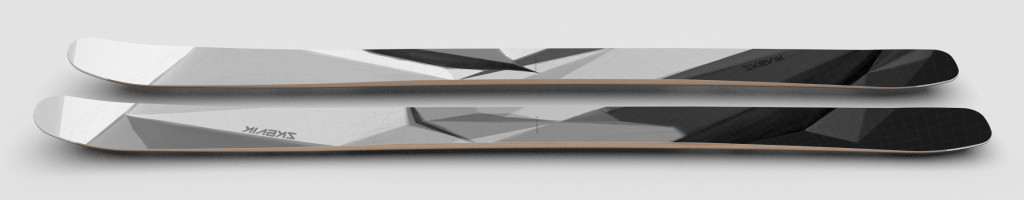

Skevik Skis – Local Skis for Local Skiers

Photo – Geoff Holman

How cool would it be to make your own skis? I’ve skied on just about everything out there and I do have some favourites, but I’ve always wondered what it would be like to actually make your own skis. You could build them to your exact specs, take everything that you like from other companies and combine them to make your own uber ski.

Photo – Skevik Skis

Over the last ten years, the ski industry has seen an increase in small, independent ski manufacturing. Surprising, considering the trends in most industries for off shore production, labour outsourcing and generally trying to make things as cheap as possible to sell for as much as possible. Companies like Prior, Folsom, Liberty and Icelantic have all slowly increased in size and production and many of these companies are making skis in the US and Canada. And what’s more interesting is that a lot of these manufacturers are matching the prices of the big ski companies.

Photo – Skevik Skis

One such company is Skevik Skis. Located in Vernon, BC, which is blessed with some of the driest snow on earth, brothers Glenn and Gregg Anderson took their love for tinkering, passion for skiing and ambition to make skiing a way of life and started a ski company. Not an easy thing to do. When older brother Gregg was working in the repair shop at Silver Star, he spent a lot of his down time taking apart old skis and seeing how they were made.

Photo – Matthew Butterworth

“After cutting up a bunch of skis, my brother saw that they weren’t really that hard to make and that maybe we should try making them ourselves.” said Glenn, who is the younger of the two. At the time, Glenn was still in high school. Not being able to afford a proper press, the brothers decided to make one from scratch. The first few attempts were, well, challenging. “While our first few skis didn’t work all that well, they didn’t break, and that was encouraging,” said Glenn.

Photo – Skevik Skis

By the time Glenn was studying mechanical engineering at the University of Victoria, they had decided they were ready for the next level: staring a ski company. After convincing the engineering faculty at UVIC to let Glenn use a ski manufacturing company startup as his “co-op” experience for the his degree, Skevik skis was born. Named after their great grandfather, Anton Martin Skevik, a Norwegian, Skevik Skis has been going strong for eight years. From their flagship fat ski, the Anton, to their latest offerings, the Loken 106 and 116, Skevik makes hand built, big mountain chargers that absolutely rip.

Photo – Geoff Holman

For those of us in the business of skiing some of the deepest snow on earth, we couldn’t think of a better testing ground for Skevik than at Last Frontier Heliskiing. So this year we hope to have a few different options from Skevik for you to choose from at one of our remote lodges in Northern BC. For more info on Skevik skis go to www.skevikskis.com

Be safe, ski hard.